PRODUCTS

GRP/FRP Grating

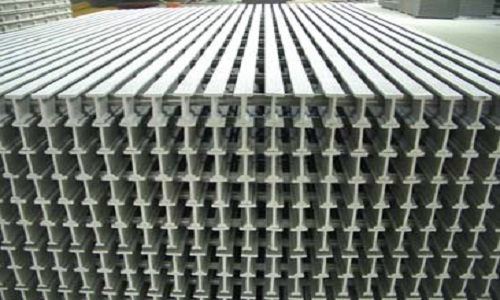

Emerald Steel IndustrieLLC. is the leading supplier and manufacturer of various GRP / FRP Grating. FRP / GRP Grating Structural profiles are manufactured using a pultrusion process (polymerization of a profile pulled through a heated die) and contain up to 70% fiberglass, ensuring exceptional mechanical strength. Their structure, composed of continuous directional glass fibers, gives them excellent resistance to impact and fatigue (overloading does not cause permanent deformations). FRP (Fiber Reinforced Plastic) pultruded profiles have various advantages: extraordinary rigidity, corrosion resistance, electrical insulation, and are lightweight. Designed by specialists in composite structures, pultruded profiles take into account all the properties required in a load-bearing profile or beam, such as longitudinal strength, shear resistance, flange flexural resistance, and transversal strength. Applications for pultruded profiles and self-supporting structures, pultruded fiberglass profiles are designed to be used as structural supports with all the necessary performance guarantees. Emerald Steel Industries LLC., is an industry-leading GRP/FRP Grating supplier in UAE and Middle East regions.

- Molded / Pultruded Grating

- Mini Mesh Grating

- Grating Platform

- Molded Grating

- Pultruded Grating

- Stair Tread

Emerald Steel Industries offers two types of quality fiberglass grating, molded and pultruded. Both types are lightweight and easy to install. Molded grating is unmatched in its ability to withstand the effects of corrosion and is highly impact resistant. Pultruded grating provides reliable corrosion resistance and high load bearing characteristics.

Fiberglass grating weighs less than half that of steel, is simple to fabricate and is less expensive to install. FRP grating exceeds the requirements for grating used in even the most demanding applications. In industries such as chemical, refining, offshore, pulp and paper, food and beverage, marine (including military vessels), water and wastewater treatment, electronics and plating, Fiber grate grating is proven to deliver years of reliable service.

- Molded/Pultruded

- Resin system

- Grating thickness

- Mesh Pattern

- Panel sizes needed

- Grit or concave top

FRP Mini-mesh Grating is a special FRP Molded Grating, with a cross bar at the top of the grating. The cross bar forms a smaller hole size at the top of the grating, which could protect small sized items from dropping through the holes.

Advantages of frp mini mesh grating

- High anti-fire

- High anti-corrosion and anti-aging

- High anti-slippery

- Light,but high loaded strength

- Long service life and maintenance free

- Non-conduction or magnetic

- Easy installation and rich colors

- Various sizes and colors available

- It has been widely used in areas such as: industrial , commercial , recreational such as:walkway, operation platform, drilling platforms, stair treads, equipment walkways, trench cover, pedestrian over bridge, ship deck, scaffolding floor, ventilation gate, fence,etc.

Product Application

Golden Fiberglass is light weight,height strength,Non-Conductive,Corrosion Resistant,Slip Resistant and No Welding required.Widely used by:

Chemical Plants

Having excellent resistant to corrosion, FRP grating is extensively used in Chemical Plants.It is mainly used operation platform,walkways,oil storage tanks,power distribution boards and rooms.etc.

Manufacture

FRP grating can be used as Walkways,Fencing,Racks and shelving,Wash racks,Scaffolding,Drainage pit covers Stairs,etc.

Transportaion

FRP grating can be used as access ways,Platforms(static resistant),docks,trenches,tanker,Stairs,Freight car flooring fill areas as well as walking surfaces and in work areas,etc.

Water and Sewage Water

FRP grating are environmentally safe and can be used extensively as filter media support,access walkways,trench Scaffolding,manhole cover,walkovers Scaffolding and Fencing,Stairs,etc.

Products Detail

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

FRP Molded Grating Strong Points:

- Corrosion ResistanceDifferent types of resin provide their own different anti-corrosion properties, which could be used in different corrosion circumstance such as acid, alkali, salt, organic solvent (in gas or liquid form) and the like over a long period.

- Fire ResistanceOur special formula provide grating with excellent fire resistant performance. Our FRP gratings pass ASTM E-84 Class 1.

- Light Weight & High StrengthThe perfect combination of the continuous E-glass roving and thermosetting polyester resin provide grating with light weight and high strength and its specific gravity is only 1/4 of that of steel, 1/3 of aluminum. Its rigidity is up to and even exceeds that of steel. Different thickness and mesh size bring the client more choice.

- Safety & Anti-slipThe high modulus of elasticity and various surfaces provided the super anti-skid performances. Its surface could be smooth surface, meniscus surface, grit surface and chequer plate cover which is suitable for different working places.

- Electrical InsulatingHigh strength E-glass roving and high-grade resin provide the product super electric performance. Its electric break strength could reach 10KV/mm. There is no electric spark even when impact by tools, meanwhile it is non-magnetism. FRP Molded Grating could be used safely under the antiknock, diamagnetism and electric-resistance environments.

- Aging ResistanceThe high-grade resin and anti-ageing stabilizer provide grating long-life ageing resistant performance and the unique design make grating excellent self-cleanness function and keep its brightness and strength over a long time. The service life of grating could be 25 years.

Products Detail

The 65% glass to 35% resin ratio of pultruded grating provides twice the stiffness of molded grating, allowing it to span greater distances. Pultruded grating is best suited to pedestrian walkways, platforms, and other applications where wide support spans, close load bar spacing, or ADA compliance is required. Safe-T-Span pultruded gratings are offered in a variety of panel sizes, depths, tie bar spacing and open area.

Feature:

- Corrosion Resistant

- Slip Resistant

- Fire Retardant

- High Strength-to-Weight Ratio

- Non-Conductive

- Low Installation Cost

- Long Service Life

- Superior Ergonomics

Specifications:

- Corrosion resistence, long service life

- Light Weight,high strength

- Non-electrical conduction

- Maintenance free

Excellent properties

- Safety:FRP is recommended when corrosion protection and safety are your goal.

- Stability:Expansion and contraction is 24% and 50% less than aluminum and steel, providing greater dimensional stability.

- Durability:Superior durability to Stainless Steel, Aluminum, and Galvanized Gratings, especially in highly corrosive environments.

- Strength:50%higher tensile strength than hot rolled steel and better impact resistance.

Cutting method:

Serging four side,Serging three sides,Serging opposite sides,Serging the neighboring sides,Non-serginh.

Surface Treatment:

Smooth surface grating,Concave surface grating, Microvoid grating, Sandy grating,Cover board gratin,Transparent grating

- Smooth surface and italic grid make it easy to clean.

- Cross distributing loads equally to improve the bearing capacity.

- Surface grooves prevent slipping, covered sand type is better in anti-slipping.

Installation manual:

Three types of stainless steel Standard fixture: L, M, C

Use stainless steel clamp to connect gratings and fix the grating and frame.