PRODUCTS

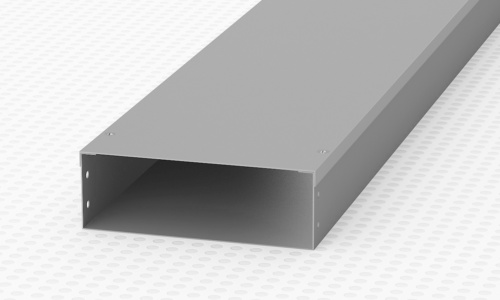

Trunking

Cable Trunking is an integral part of any cable management system, without this essential component cables will be left exposed putting the professionals providing maintenance in the future and your customers at risk. As a leading supplier of single compartment trunking and twin compartment trunking, here at Emerald Steel Industries LLC Ajman, UAE , we certainly know a thing or two about the importance of cable protection and as we are the largest manufacturers of Cable Trunking Products in UAE and suppliers of Cable Trunking products all over inside UAE and other Gulf Countries like Oman,Saudi Arabia,Qatar,Kuwait,Bahrain etc , Africa,Europe and thanks to a range of cable trunking systems available you can harness the advantages of a flexible and reliable support solution.

As well as providing single compartment trunking and twin compartment trunking, we also provide end stops, end caps, outlet flanges, stirrup hangers, spare trunking, speed locks, separators, overhead hook hangers, standoff brackets, internal flat 90 degree bends, 45 degree internal bends and 45 degree external bends. In addition to this, we also deliver trunking made specifically for lighting cables and three compartment cable trunking so more complex cable systems can be fully protected .

• Emerald’s CableTrunking products manufactured in UAE is designed to provide a simple method of containing lightweight and structured cables. It is designed to meet all the requirements of BS 4678 & BS 50085 We offer a comprehensive range of standard Surface Trunking in single or multi-compartment.

• Both the trunking and the body are supplied in 3 meter lengths complete with coupler and all necessary fixing screws.

• Emerald Trunking System is designed to provide containment for light applications such as Structured Cables and LV Systems.

• It fully complies with the requirement of

• BS 4678 / BS 50085.

Materials and Finishes

-Pre-Galvanized zinc coated steel JIS G3302 equivalent to BS EN 10142, (BS EN10142 supersedes BS2989), ASTM A653.

-Pre-Galvanized zinc coated steel JIS G3302 equivalent to BS EN 10142, (BS EN10142 supersedes BS2989), ASTM A653 with Epoxy Powder Coating with minimum film thickness 60 microns after fabrication.

-Hot dip galvanized with using Hot Rolled Steel to BS 10149-3:1996, Cold Rolled Steel to BSEN 10130:2006 then post galvanizing as per BS EN 1461

(Formerly BS729), ASTM-A 123.

-Stainless Steel Sheet to ASTM A240 type 304, 316L.

-Aluminum Grade AA 1100.